How does the application of serpentine tube products in economizers achieve energy saving?

Release Time : 2025-01-09

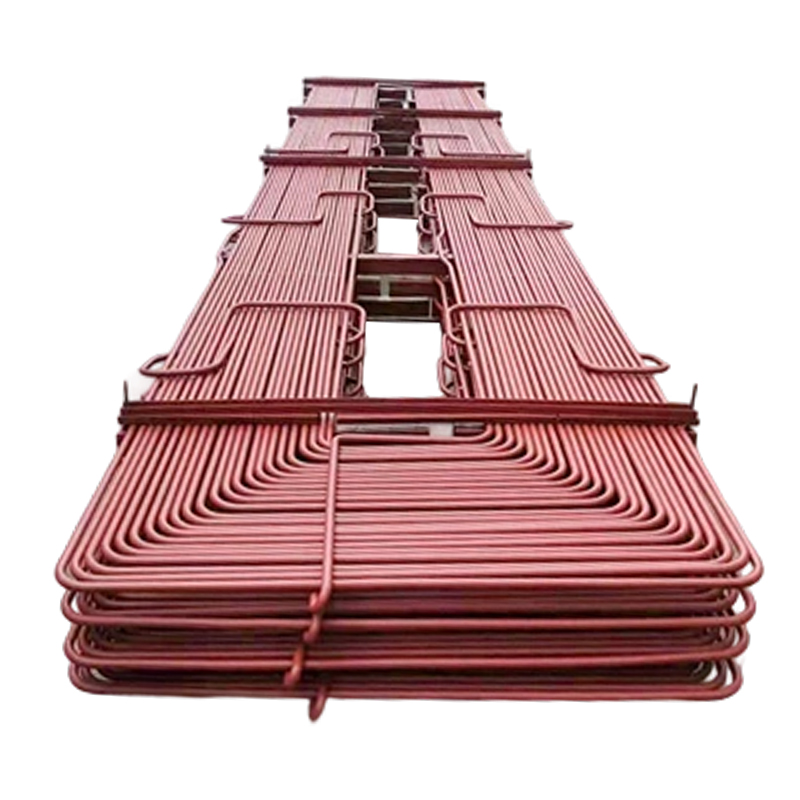

The application of serpentine tube products in economizers can significantly improve thermal efficiency and thus achieve energy saving effects.

1. Increase heat exchange area

The structural feature of serpentine tube products is that the length of the tube is increased by bending it into a serpentine shape, thereby increasing the heat exchange area. A larger heat exchange area means that the heat exchange between flue gas and water is more complete, which can more effectively utilize the waste heat of flue gas and improve thermal efficiency.

2. Optimizing fluid flow

Serpentine tube products are designed to optimize fluid flow and create turbulence within the tube. Turbulence increases the contact area between the fluid and the tube wall, improves the heat transfer coefficient, and thus enhances the heat exchange effect. At the same time, turbulence can also reduce the thickness of the boundary layer and further improve the heat transfer efficiency.

3. Reduce thermal resistance

The curved design of serpentine tube products can reduce thermal resistance. In conventional straight tube heat exchangers, heat transfer may be affected by the flow boundary layer, resulting in increased thermal resistance. The design of serpentine tube products reduces thermal resistance by increasing the turbulence of the fluid and reducing the impact of the boundary layer.

4. Uniform temperature distribution

The design of serpentine tube products can ensure a more uniform temperature distribution between flue gas and water during the heat exchange process. This helps avoid local overheating and improves the thermal efficiency of the entire economizer. Even temperature distribution can also extend the life of the equipment and reduce maintenance costs.

5. Improve heat recovery efficiency

The main function of the economizer is to use the waste heat of the flue gas to preheat the boiler feed water, thereby reducing fuel consumption. The high efficiency heat exchange capacity of serpentine tube products can recover the heat in the flue gas to the maximum extent and improve the heat recovery efficiency. The higher feed water temperature after preheating can reduce the fuel demand of the boiler, thus achieving energy savings.

6. Reduce the flue gas emission temperature

Through efficient heat exchange, serpentine tube products can reduce the temperature of flue gas to a lower level. This means more waste heat is recovered and less unused heat energy is left in the flue gases. Lowering the flue gas emission temperature not only improves thermal efficiency, but also helps reduce environmental emissions.

7. Reduce heat loss

The design of serpentine tube products can also reduce heat loss. Because serpentine tube products increase the heat exchange area and turbulence, the heat transfer is more complete and the loss of heat energy is reduced. This helps to improve the thermal efficiency of the entire system and achieve energy savings.

8. Adaptability

Serpentine tube products have high adaptability in structure and can be flexibly installed in different locations and spaces. This flexibility allows the economizer to better adapt to various boilers and flue gas systems, improving its energy-saving effect.

The application of serpentine tube products in economizers has the following advantages: increasing heat exchange area, optimizing fluid flow, reducing thermal resistance, uniform temperature distribution, improving heat recovery efficiency, reducing flue gas emission temperature, reducing heat loss and having strong adaptability. This improves thermal efficiency and achieves energy saving. These features make serpentine tube products an efficient and reliable energy-saving technology in boiler systems.

1. Increase heat exchange area

The structural feature of serpentine tube products is that the length of the tube is increased by bending it into a serpentine shape, thereby increasing the heat exchange area. A larger heat exchange area means that the heat exchange between flue gas and water is more complete, which can more effectively utilize the waste heat of flue gas and improve thermal efficiency.

2. Optimizing fluid flow

Serpentine tube products are designed to optimize fluid flow and create turbulence within the tube. Turbulence increases the contact area between the fluid and the tube wall, improves the heat transfer coefficient, and thus enhances the heat exchange effect. At the same time, turbulence can also reduce the thickness of the boundary layer and further improve the heat transfer efficiency.

3. Reduce thermal resistance

The curved design of serpentine tube products can reduce thermal resistance. In conventional straight tube heat exchangers, heat transfer may be affected by the flow boundary layer, resulting in increased thermal resistance. The design of serpentine tube products reduces thermal resistance by increasing the turbulence of the fluid and reducing the impact of the boundary layer.

4. Uniform temperature distribution

The design of serpentine tube products can ensure a more uniform temperature distribution between flue gas and water during the heat exchange process. This helps avoid local overheating and improves the thermal efficiency of the entire economizer. Even temperature distribution can also extend the life of the equipment and reduce maintenance costs.

5. Improve heat recovery efficiency

The main function of the economizer is to use the waste heat of the flue gas to preheat the boiler feed water, thereby reducing fuel consumption. The high efficiency heat exchange capacity of serpentine tube products can recover the heat in the flue gas to the maximum extent and improve the heat recovery efficiency. The higher feed water temperature after preheating can reduce the fuel demand of the boiler, thus achieving energy savings.

6. Reduce the flue gas emission temperature

Through efficient heat exchange, serpentine tube products can reduce the temperature of flue gas to a lower level. This means more waste heat is recovered and less unused heat energy is left in the flue gases. Lowering the flue gas emission temperature not only improves thermal efficiency, but also helps reduce environmental emissions.

7. Reduce heat loss

The design of serpentine tube products can also reduce heat loss. Because serpentine tube products increase the heat exchange area and turbulence, the heat transfer is more complete and the loss of heat energy is reduced. This helps to improve the thermal efficiency of the entire system and achieve energy savings.

8. Adaptability

Serpentine tube products have high adaptability in structure and can be flexibly installed in different locations and spaces. This flexibility allows the economizer to better adapt to various boilers and flue gas systems, improving its energy-saving effect.

The application of serpentine tube products in economizers has the following advantages: increasing heat exchange area, optimizing fluid flow, reducing thermal resistance, uniform temperature distribution, improving heat recovery efficiency, reducing flue gas emission temperature, reducing heat loss and having strong adaptability. This improves thermal efficiency and achieves energy saving. These features make serpentine tube products an efficient and reliable energy-saving technology in boiler systems.