What are the technical features of boiler evaporator module products?

Release Time : 2024-12-25

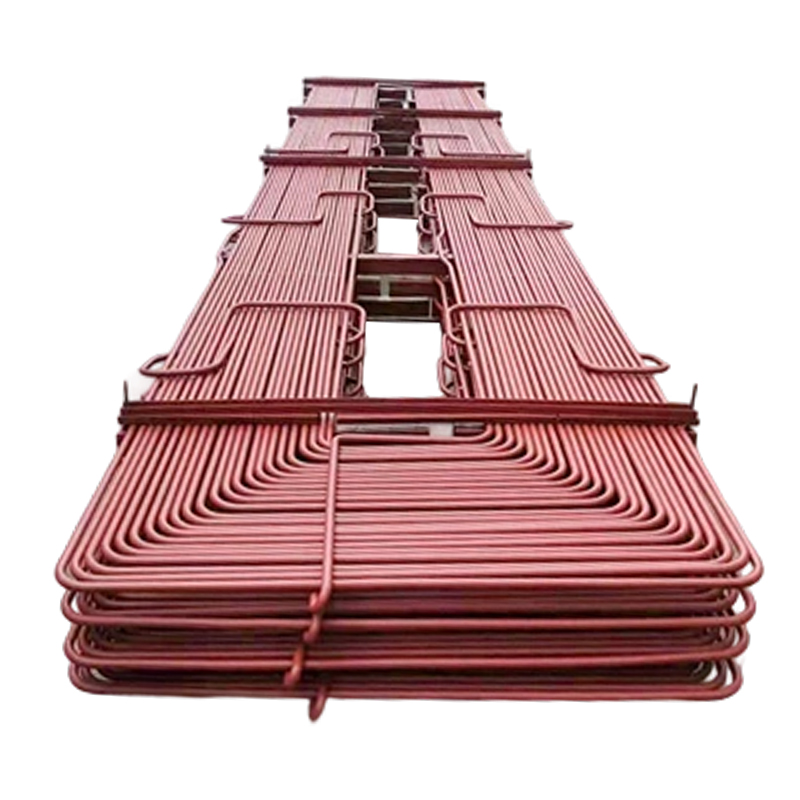

The boiler evaporator module product integrates a number of advanced technologies and has a variety of significant technical features. The following is a detailed introduction:

1. Modularity and flexibility

Module combination: Boiler evaporator module products are jointly controlled through multiple module units that can operate independently. They can be "simple parallel combination" in quantity according to actual needs to meet different heating or steam needs.

Flexible adjustment: Modular boilers can intelligently adjust the number of modular units according to actual heat load needs to achieve refined energy saving. At the same time, the modular boiler system is equipped with a hierarchical start function, which can automatically adjust the start and stop of the modular boiler according to the system's set temperature to ensure that the output heat matches the actual demand heat load.

2. High efficiency and energy saving

High thermal efficiency: A tube-fin heat exchanger is used inside the modular boiler. The water flow is instantly vaporized in the pipeline. At the same time, the special aluminum alloy fire exhaust hole layer is burned. The combustion is more uniform and stable. The thermal efficiency can be stably maintained at a high level (such as 95% about). Some products also use condensation heat transfer technology, using the latent heat of vaporization in the flue gas to heat water, further improving thermal efficiency (up to 108%).

Energy-saving technology: Full premixed combustion technology allows gas and air to be completely premixed, resulting in more complete combustion and a more complete release of gas chemical energy. It also reduces air pollutants and flue gas volume, and reduces exhaust heat loss.

3. Intelligence and automation

Intelligent control: The modular boiler adopts an advanced computer micro-control system, which can automatically adjust the output power and start the module unit according to the set heating temperature curve and other parameters, and with reference to the monitoring and calculation of outdoor temperature and supply and return water temperature changes. quantity. At the same time, the system has the characteristics of stable performance and high degree of automation, and can realize unattended mode.

Self-protection: Modular boilers have multiple safety protection functions in the combustion system, such as flameout protection, dry burning protection, wind pressure protection, automatic exhaust protection, overheating protection, leakage protection, etc. In addition, the waterway system is also equipped with high and low pressure protection functions and safety pressure relief devices to ensure the safety and reliability of the entire machine.

4. Easy to maintain and save space

Easy to maintain: The modular boiler adopts a single-machine multi-module design. Even if one module fails, other modules can continue to operate, and the entire machine can operate with faults without affecting production. At the same time, the device will automatically display fault codes to facilitate quick location and solution of problems.

Save space: The modular boiler has a unique design, is small and saves floor space. At the same time, modular boilers do not require a boiler room and can save infrastructure costs.

5. Wide application

Wide scope of application: Boiler evaporator module products are suitable for a variety of places and needs, such as factories, hotels, hotels, enterprises and institutions, canteens of large universities, hospitals, etc., and can meet various uses such as cooking, heating, disinfection, and heating. need.

Boiler evaporator module products have the characteristics of modularity and flexibility, high efficiency and energy saving, intelligence and automation, easy maintenance and space saving, and wide application. These characteristics make modular boilers play an increasingly important role in modern industrial production and life.

1. Modularity and flexibility

Module combination: Boiler evaporator module products are jointly controlled through multiple module units that can operate independently. They can be "simple parallel combination" in quantity according to actual needs to meet different heating or steam needs.

Flexible adjustment: Modular boilers can intelligently adjust the number of modular units according to actual heat load needs to achieve refined energy saving. At the same time, the modular boiler system is equipped with a hierarchical start function, which can automatically adjust the start and stop of the modular boiler according to the system's set temperature to ensure that the output heat matches the actual demand heat load.

2. High efficiency and energy saving

High thermal efficiency: A tube-fin heat exchanger is used inside the modular boiler. The water flow is instantly vaporized in the pipeline. At the same time, the special aluminum alloy fire exhaust hole layer is burned. The combustion is more uniform and stable. The thermal efficiency can be stably maintained at a high level (such as 95% about). Some products also use condensation heat transfer technology, using the latent heat of vaporization in the flue gas to heat water, further improving thermal efficiency (up to 108%).

Energy-saving technology: Full premixed combustion technology allows gas and air to be completely premixed, resulting in more complete combustion and a more complete release of gas chemical energy. It also reduces air pollutants and flue gas volume, and reduces exhaust heat loss.

3. Intelligence and automation

Intelligent control: The modular boiler adopts an advanced computer micro-control system, which can automatically adjust the output power and start the module unit according to the set heating temperature curve and other parameters, and with reference to the monitoring and calculation of outdoor temperature and supply and return water temperature changes. quantity. At the same time, the system has the characteristics of stable performance and high degree of automation, and can realize unattended mode.

Self-protection: Modular boilers have multiple safety protection functions in the combustion system, such as flameout protection, dry burning protection, wind pressure protection, automatic exhaust protection, overheating protection, leakage protection, etc. In addition, the waterway system is also equipped with high and low pressure protection functions and safety pressure relief devices to ensure the safety and reliability of the entire machine.

4. Easy to maintain and save space

Easy to maintain: The modular boiler adopts a single-machine multi-module design. Even if one module fails, other modules can continue to operate, and the entire machine can operate with faults without affecting production. At the same time, the device will automatically display fault codes to facilitate quick location and solution of problems.

Save space: The modular boiler has a unique design, is small and saves floor space. At the same time, modular boilers do not require a boiler room and can save infrastructure costs.

5. Wide application

Wide scope of application: Boiler evaporator module products are suitable for a variety of places and needs, such as factories, hotels, hotels, enterprises and institutions, canteens of large universities, hospitals, etc., and can meet various uses such as cooking, heating, disinfection, and heating. need.

Boiler evaporator module products have the characteristics of modularity and flexibility, high efficiency and energy saving, intelligence and automation, easy maintenance and space saving, and wide application. These characteristics make modular boilers play an increasingly important role in modern industrial production and life.