How do water wall products ensure uniform and stable heating of the boiler by virtue of their circulation characteristics?

Release Time : 2024-12-11

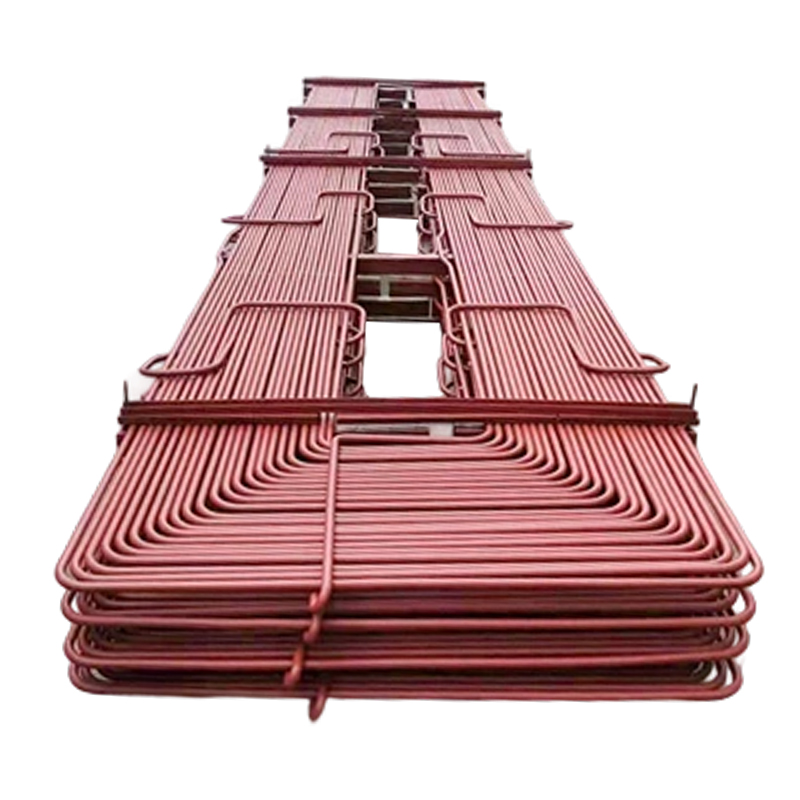

Water wall products are key components in modern boiler systems. They transfer heat by converting water into steam while protecting the boiler walls from high temperatures and pressures. Water wall products are designed to ensure uniform and stable heating of the boiler, which is achieved primarily through their circulation characteristics.

1. Natural circulation water wall products

Principle: Natural circulation water wall products rely on density differences to drive the flow of water and steam. During boiler operation, the water in the water wall product tube absorbs heat and partially evaporates into steam, forming a steam-water mixture. Since the density of steam is less than that of water, this density difference creates a circulation driving force, causing the steam-water mixture to rise to the steam drum, while the heavier water flows back from the steam drum to the bottom of the water wall product, forming a continuous cycle.

Advantages:

Self-compensation capability: The natural circulation system has a self-compensation characteristic, that is, when the heat load increases, the circulation flow rate will also increase, thereby improving the heat transfer efficiency and helping to maintain a uniform temperature on the heating surface.

Simple structure: The system is relatively simple and easy to maintain and manage.

2. Forced circulation water wall products

Principle: Forced circulation water wall products force the flow of circulating water and steam through pumps. Water in the boiler is pumped through the water wall products tubes, absorbs heat and becomes steam, and then returns to the steam drum or separator. This system does not rely on natural density differences, but relies on the pressure of the pump to maintain circulation.

Advantages:

Higher circulation flow rate: Forced circulation can achieve higher water flow rate, improve heat transfer coefficient, allow higher heat load and better temperature control.

Flexibility: The system can adapt to different load changes and operating conditions more flexibly.

3. Mixed circulation water wall products

Principle: Mixed circulation combines the characteristics of natural circulation and forced circulation. In some designs, the main circulation is driven by a pump, while some areas may rely on natural circulation.

Advantages:

Comprehensive advantages: Combining the advantages of two circulation methods, providing better thermal performance and operational flexibility.

Reliability: Improve system reliability and redundancy through multiple circulation paths.

4. Key factors of circulation characteristics

Circulation flow rate: Appropriate circulation flow rate is the key to ensure uniform heating of water wall products. Too low a flow rate may lead to deterioration of heat transfer and local overheating, while too high a flow rate may increase flow resistance and energy consumption.

Heat load distribution: Uniform heat load distribution helps to avoid local overheating. The distribution of heat load can be optimized by properly designing the layout and spacing of water wall products.

Water quality management: Good water quality control can prevent scaling and corrosion in the water wall products tube, maintain good heat transfer performance and smooth circulation channels.

Monitoring and control: Real-time monitoring of the temperature, pressure and flow parameters of water wall products, and adjusting the speed or other parameters of the circulation pump through the control system to maintain the best operating state.

The circulation characteristics of water wall products are essential to ensure uniform heating and stable operation of the boiler. By properly designing and managing the circulation system, the efficiency and life of the boiler can be maximized, while ensuring safe operation and environmental friendliness.

1. Natural circulation water wall products

Principle: Natural circulation water wall products rely on density differences to drive the flow of water and steam. During boiler operation, the water in the water wall product tube absorbs heat and partially evaporates into steam, forming a steam-water mixture. Since the density of steam is less than that of water, this density difference creates a circulation driving force, causing the steam-water mixture to rise to the steam drum, while the heavier water flows back from the steam drum to the bottom of the water wall product, forming a continuous cycle.

Advantages:

Self-compensation capability: The natural circulation system has a self-compensation characteristic, that is, when the heat load increases, the circulation flow rate will also increase, thereby improving the heat transfer efficiency and helping to maintain a uniform temperature on the heating surface.

Simple structure: The system is relatively simple and easy to maintain and manage.

2. Forced circulation water wall products

Principle: Forced circulation water wall products force the flow of circulating water and steam through pumps. Water in the boiler is pumped through the water wall products tubes, absorbs heat and becomes steam, and then returns to the steam drum or separator. This system does not rely on natural density differences, but relies on the pressure of the pump to maintain circulation.

Advantages:

Higher circulation flow rate: Forced circulation can achieve higher water flow rate, improve heat transfer coefficient, allow higher heat load and better temperature control.

Flexibility: The system can adapt to different load changes and operating conditions more flexibly.

3. Mixed circulation water wall products

Principle: Mixed circulation combines the characteristics of natural circulation and forced circulation. In some designs, the main circulation is driven by a pump, while some areas may rely on natural circulation.

Advantages:

Comprehensive advantages: Combining the advantages of two circulation methods, providing better thermal performance and operational flexibility.

Reliability: Improve system reliability and redundancy through multiple circulation paths.

4. Key factors of circulation characteristics

Circulation flow rate: Appropriate circulation flow rate is the key to ensure uniform heating of water wall products. Too low a flow rate may lead to deterioration of heat transfer and local overheating, while too high a flow rate may increase flow resistance and energy consumption.

Heat load distribution: Uniform heat load distribution helps to avoid local overheating. The distribution of heat load can be optimized by properly designing the layout and spacing of water wall products.

Water quality management: Good water quality control can prevent scaling and corrosion in the water wall products tube, maintain good heat transfer performance and smooth circulation channels.

Monitoring and control: Real-time monitoring of the temperature, pressure and flow parameters of water wall products, and adjusting the speed or other parameters of the circulation pump through the control system to maintain the best operating state.

The circulation characteristics of water wall products are essential to ensure uniform heating and stable operation of the boiler. By properly designing and managing the circulation system, the efficiency and life of the boiler can be maximized, while ensuring safe operation and environmental friendliness.