Industry News

What are the requirements for setting flow measurement points in circulating fluidized bed boilers? How to prevent water-cooled walls from wear?

What are the regulations for setting the total flow measurement point of fluidized bed boiler in circulating system?

(1) The turbine flowmeter should be flanged, flanged and clamped for testing.

(2) Turbine flow meters cannot be installed on negative pressure pipelines. When installing, ensure that the pipe is full or a siphon should be arranged on the pipe. The material to be measured in the pipeline should be short-circuited to the ground and have zero potential difference.

(3) The vortex flowmeter should be installed in an area away from oscillation sources and strong interference signals, and shock-absorbing equipment can be used.

(4) The shell of the target flowmeter should be safely and reliably grounded and installed on a pipeline with bypass. After installation, the steam flowmeter should be set to zero when there is no material flow in the pipeline. High-temperature and low-temperature steam flowmeters should be The temperature inside the pipe reaches zero operating temperature.

What are the requirements for the layout and installation of measurement points for carbonated beverage system software?

(1) The base and outer tube should be installed before the pressure test, and should be connected by electric welding. No holes or electric welding should be made on the welding and edges of the main pipe.

(2) If the working pressure sampling hole and the testing instrument are not at the same relative height, the working pressure should be compensated or transferred.

(3) The inclination of the horizontal pipe should not be less than 1:100.

(4) The primary and secondary sampling doors should use high-temperature and high-pressure welded valves.

(5) The local barometer should be made of durable metal material, with a shock-proof laminated glass cover. The watch case and strap should be strong, and the needle should have an adjustment device.

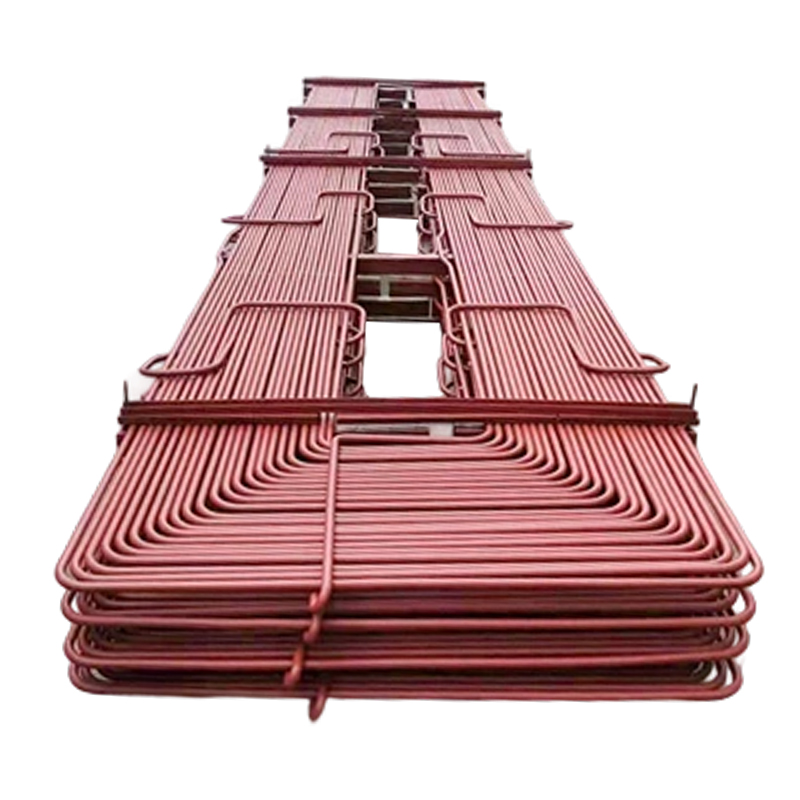

How to prevent water-cooled wall from wearing

How to reasonably and effectively prevent wear of circulating system fluidized bed boilers has always puzzled many thermal power plants. With the release of Geshan anti-wear technology, the problem of water wall damage can be completely eradicated. Geshan anti-wear technology is an active anti-wear technology for water-cooled walls. It has complete anti-wear effect and long anti-wear cycle. It is currently the core anti-wear technology for water-cooled walls.

What are the requirements for the arrangement and installation of measuring points in the circulating fluidized bed boiler air system?

Temperature measuring points should meet the following requirements:

(1) When the insertion depth exceeds lm, anti-bending measures should be taken.

(2) The measuring point should be installed at an angle, preferably at an angle of 45°. It should be opposite to the direction of material flow and can be installed vertically with the axis of the pipeline.

(3) The measuring point in front of the air preheater should be installed with threads, and the measuring point after the air preheater should be installed with a flange.

Working pressure measuring points should meet the following requirements:

(1) The diameter of the pressure sensing device should be consistent with the diameter of the pressure sensing device. It is advisable to use a pneumatic pressure sensing device with a standing depositor.

(2) The top of the working pressure source component is flush with the middle wall of the air duct, and the source component should be installed tilted upward. Horizontal pipes should be installed at an obtuse angle along the water. When installed on high-capacity and inclined pipelines, the pressure tapping hole should be opened in the upper half of the processing pipeline.

The total flow measurement point should meet the following requirements:

(1) The measuring point should be taken on a straight pipe, and the length of the straight pipe should be in accordance with the specifications of "Technical Requirements for On-site Equipment Installation, Pipe and Cable Design of Insulated Automation Technology for Thermal Power Plants" (DL/T 5182-2004) The selection should meet the requirements of total flow equipment layout and precise measurement.

(2) Precise measurement equipment such as Venturi nozzle type, velocity averaging tube, and aircraft wing should be used. The total flow of air conveying air can be measured by a packing flow measuring device.

Geshan anti-corrosion technology completely eliminates the problem of reheater damage

The reheater damage problem of circulating fluidized bed boilers is one of the common and unsolvable problems in thermal power plants. With the release of Geshan anti-corrosion technology, the reheater damage problem will not be an unsolvable problem.

For the best biomass steam generator, choose Huayi Special Equipment

With the continuous progress and development of science and technology and the increasing demand for steam equipment in the times, many types of steam equipment have been developed. How to choose good steam equipment among many companies is a problem that many companies and users must consider. Traditional steam heating furnaces have been gradually replaced by society, and energy-saving steam generators are favored by various industries. In this general environment, more and more companies are transforming into energy-saving directions. Zhangjiagang Huayi Special Equipment Co., Ltd. is an excellent manufacturer of energy-saving steam generator equipment, among which biomass steam generators are representatives of its energy-saving products.