How does boiler evaporator module products use heat energy to heat water into hot water?

Release Time : 2025-01-22

Boiler evaporator module products are one of the key equipment that uses heat energy to heat water into hot water or steam. Its working principle is mainly based on the principle of heat transfer.

1. Overview of working principle

The working principle of boiler evaporator module products can be simply summarized as follows: the heat energy generated by fuel combustion is transferred to the water in the boiler, causing the water temperature to rise, eventually reaching the boiling point and generating steam. In this process, the heat energy is effectively transferred to the water through different heat transfer methods (such as radiation, convection and conduction).

2. Specific work flow

Fuel combustion: In the combustion chamber of the boiler, the fuel (such as coal, oil, natural gas, etc.) is ignited and burned, releasing a large amount of heat energy.

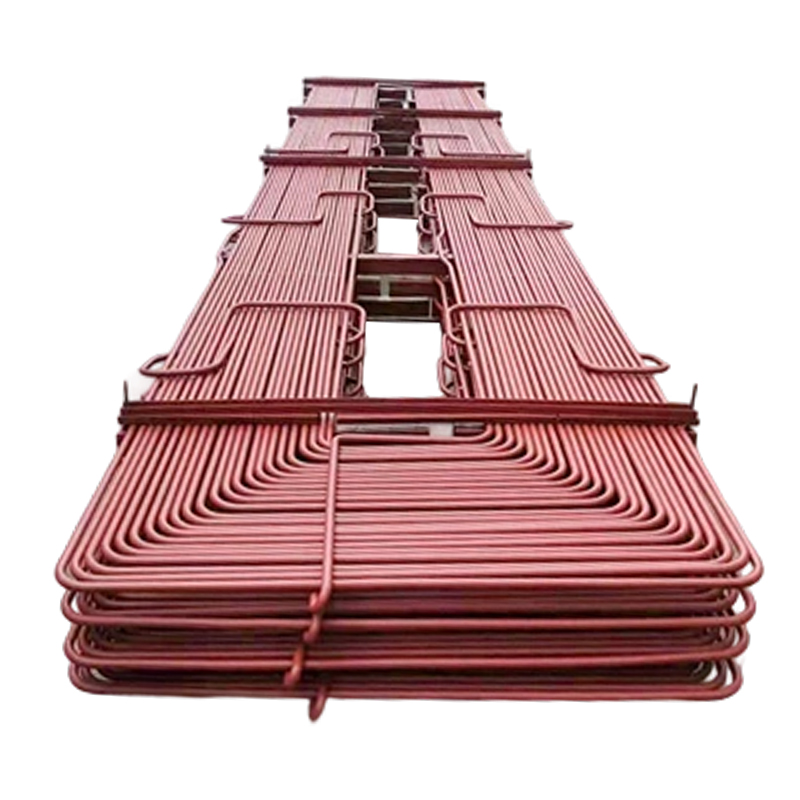

Heat transfer: The heat energy generated by combustion is transferred to the water in the boiler through the heating surface of the boiler (such as water-cooled wall, superheater, etc.). These heating surfaces are usually composed of multiple pipes, in which water flows and absorbs heat.

Water temperature rises: As the heat energy is continuously transferred, the water in the boiler gradually heats up. When the water temperature reaches the boiling point, the water begins to evaporate and produces steam.

Steam generation: In boiler evaporator module products, water evaporates quickly after being heated to form steam. The steam is then collected and transported to where it is needed for use.

3. Heat transfer methods

In boiler evaporator module products, heat energy is mainly transferred to water in the following ways:

Radiation heat transfer: The high-temperature flue gas generated by combustion transfers heat to the heating surface of the boiler by radiation. This heat transfer method mainly occurs in the space between the high-temperature flue gas and the heating surface.

Convection heat transfer: When the high-temperature flue gas flows in the boiler, it transfers heat to the heating surface and water by convection. This heat transfer method mainly occurs in the convection zone between the flue gas and the heating surface.

Conduction heat transfer: The metal material in the heating surface transfers heat to the water by conduction. This heat transfer method mainly occurs between the water inside the heating surface and the metal wall.

4. Thermal energy utilization efficiency

In order to improve the thermal energy utilization efficiency of boiler evaporator module products, the following measures are usually taken:

Optimize the design of the heating surface: By rationally designing the shape, size and layout of the heating surface, the transfer efficiency and absorption rate of thermal energy can be improved.

Enhance heat exchange: The use of efficient heat exchange technology and equipment, such as heat exchangers, economizers, etc., can further improve the utilization efficiency of thermal energy.

Reduce heat loss: By strengthening the insulation measures of the boiler and reducing the flue gas emission temperature, heat loss can be reduced and the thermal energy utilization efficiency can be improved.

In summary, boiler evaporator module products generate heat energy through fuel combustion, and transfer heat energy to water through heat transfer methods such as radiation, convection and conduction, so that it heats up and evaporates into hot water or steam. In order to improve the efficiency of thermal energy utilization, it is necessary to optimize the design of the heating surface, strengthen heat exchange and reduce heat loss.

1. Overview of working principle

The working principle of boiler evaporator module products can be simply summarized as follows: the heat energy generated by fuel combustion is transferred to the water in the boiler, causing the water temperature to rise, eventually reaching the boiling point and generating steam. In this process, the heat energy is effectively transferred to the water through different heat transfer methods (such as radiation, convection and conduction).

2. Specific work flow

Fuel combustion: In the combustion chamber of the boiler, the fuel (such as coal, oil, natural gas, etc.) is ignited and burned, releasing a large amount of heat energy.

Heat transfer: The heat energy generated by combustion is transferred to the water in the boiler through the heating surface of the boiler (such as water-cooled wall, superheater, etc.). These heating surfaces are usually composed of multiple pipes, in which water flows and absorbs heat.

Water temperature rises: As the heat energy is continuously transferred, the water in the boiler gradually heats up. When the water temperature reaches the boiling point, the water begins to evaporate and produces steam.

Steam generation: In boiler evaporator module products, water evaporates quickly after being heated to form steam. The steam is then collected and transported to where it is needed for use.

3. Heat transfer methods

In boiler evaporator module products, heat energy is mainly transferred to water in the following ways:

Radiation heat transfer: The high-temperature flue gas generated by combustion transfers heat to the heating surface of the boiler by radiation. This heat transfer method mainly occurs in the space between the high-temperature flue gas and the heating surface.

Convection heat transfer: When the high-temperature flue gas flows in the boiler, it transfers heat to the heating surface and water by convection. This heat transfer method mainly occurs in the convection zone between the flue gas and the heating surface.

Conduction heat transfer: The metal material in the heating surface transfers heat to the water by conduction. This heat transfer method mainly occurs between the water inside the heating surface and the metal wall.

4. Thermal energy utilization efficiency

In order to improve the thermal energy utilization efficiency of boiler evaporator module products, the following measures are usually taken:

Optimize the design of the heating surface: By rationally designing the shape, size and layout of the heating surface, the transfer efficiency and absorption rate of thermal energy can be improved.

Enhance heat exchange: The use of efficient heat exchange technology and equipment, such as heat exchangers, economizers, etc., can further improve the utilization efficiency of thermal energy.

Reduce heat loss: By strengthening the insulation measures of the boiler and reducing the flue gas emission temperature, heat loss can be reduced and the thermal energy utilization efficiency can be improved.

In summary, boiler evaporator module products generate heat energy through fuel combustion, and transfer heat energy to water through heat transfer methods such as radiation, convection and conduction, so that it heats up and evaporates into hot water or steam. In order to improve the efficiency of thermal energy utilization, it is necessary to optimize the design of the heating surface, strengthen heat exchange and reduce heat loss.