How to solve the problem of thermal expansion and contraction between pipe fittings and pipelines?

Release Time : 2025-02-20

In the pipeline system, the problem of thermal expansion and contraction between pipe fittings and pipelines is an important aspect that cannot be ignored. Due to temperature changes, pipes and pipe fittings will expand and contract, which may cause stress concentration, deformation, leakage and even rupture of the pipeline system. Therefore, it is crucial to take effective measures to solve this problem.

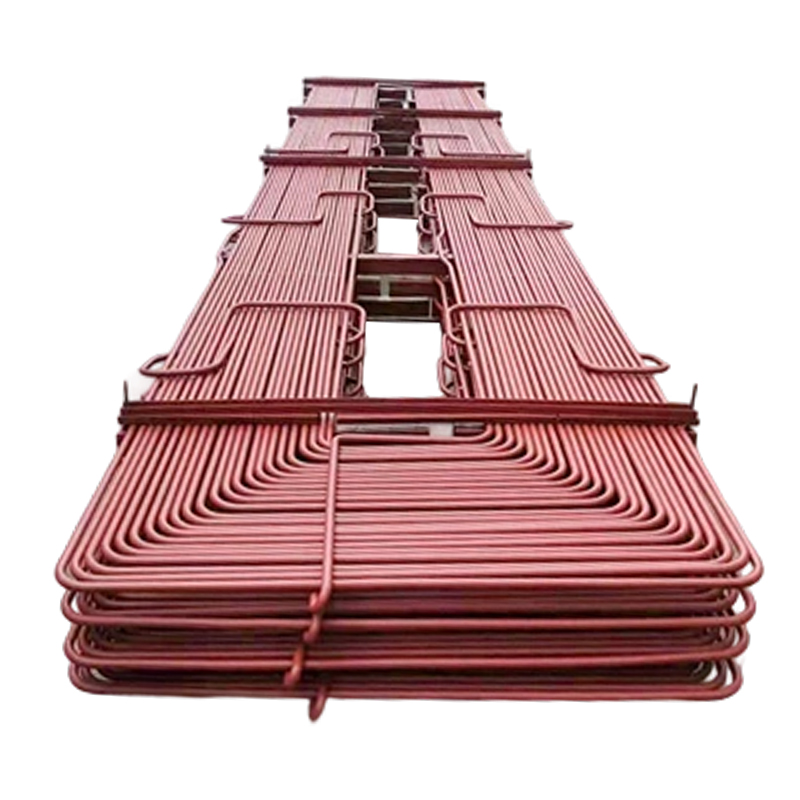

First of all, the reasonable design of pipeline layout is the basis for preventing thermal expansion and contraction problems. In pipeline design, long-distance straight laying should be avoided, and "L" or "Z" shaped bending sections should be appropriately set. These bending sections can use their elastic properties to naturally absorb part of the length changes caused by thermal expansion and contraction, thereby reducing the stress accumulation of the pipeline system.

Secondly, installing high-quality expansion joints is the key to solving the problem of thermal expansion and contraction. The expansion joint is a device designed to compensate for the length change of the pipeline due to temperature changes. Its internal structure is exquisitely designed, usually composed of bellows, flanges, pipes and other components, which can effectively absorb and alleviate the axial, lateral and angular displacement of the pipeline when the temperature changes. When installing the expansion joint, the appropriate type and specification should be selected according to the actual situation of the pipeline and the temperature variation range, and ensure that it is firmly and reliably connected to the pipeline.

In addition, the design of the pipe bracket is also crucial. The bracket should not only provide sufficient support to ensure the stability of the pipeline during normal operation, but also allow the pipeline to have a certain degree of freedom when it expands and contracts. A reasonably designed pipe bracket can be adjusted to a certain extent according to the thermal expansion and contraction of the pipeline, thereby reducing the stress accumulation inside the pipeline system.

In addition to the above measures, the impact of thermal expansion and contraction can also be reduced by controlling the medium temperature. For example, in heating and cooling systems, the temperature of the medium can be kept within a certain range by adjusting the flow rate, thereby reducing the amplitude of thermal expansion and contraction. In cold areas or environments with large temperature differences, it is also necessary to insulate the pipeline. Insulation measures can reduce the impact of temperature fluctuations on the pipeline and reduce the amplitude of thermal expansion and contraction.

In summary, solving the thermal expansion and contraction problem between pipe fittings and pipelines requires multiple aspects. By rationally designing pipeline layout, installing high-quality expansion joints, optimizing pipeline support design, and controlling medium temperature, we can effectively reduce the adverse effects of thermal expansion and contraction on the pipeline system and ensure the safe and stable operation of the pipeline system.

First of all, the reasonable design of pipeline layout is the basis for preventing thermal expansion and contraction problems. In pipeline design, long-distance straight laying should be avoided, and "L" or "Z" shaped bending sections should be appropriately set. These bending sections can use their elastic properties to naturally absorb part of the length changes caused by thermal expansion and contraction, thereby reducing the stress accumulation of the pipeline system.

Secondly, installing high-quality expansion joints is the key to solving the problem of thermal expansion and contraction. The expansion joint is a device designed to compensate for the length change of the pipeline due to temperature changes. Its internal structure is exquisitely designed, usually composed of bellows, flanges, pipes and other components, which can effectively absorb and alleviate the axial, lateral and angular displacement of the pipeline when the temperature changes. When installing the expansion joint, the appropriate type and specification should be selected according to the actual situation of the pipeline and the temperature variation range, and ensure that it is firmly and reliably connected to the pipeline.

In addition, the design of the pipe bracket is also crucial. The bracket should not only provide sufficient support to ensure the stability of the pipeline during normal operation, but also allow the pipeline to have a certain degree of freedom when it expands and contracts. A reasonably designed pipe bracket can be adjusted to a certain extent according to the thermal expansion and contraction of the pipeline, thereby reducing the stress accumulation inside the pipeline system.

In addition to the above measures, the impact of thermal expansion and contraction can also be reduced by controlling the medium temperature. For example, in heating and cooling systems, the temperature of the medium can be kept within a certain range by adjusting the flow rate, thereby reducing the amplitude of thermal expansion and contraction. In cold areas or environments with large temperature differences, it is also necessary to insulate the pipeline. Insulation measures can reduce the impact of temperature fluctuations on the pipeline and reduce the amplitude of thermal expansion and contraction.

In summary, solving the thermal expansion and contraction problem between pipe fittings and pipelines requires multiple aspects. By rationally designing pipeline layout, installing high-quality expansion joints, optimizing pipeline support design, and controlling medium temperature, we can effectively reduce the adverse effects of thermal expansion and contraction on the pipeline system and ensure the safe and stable operation of the pipeline system.