What is the basic working principle of boiler evaporator module products?

Release Time : 2025-03-06

The basic working principle of boiler evaporator module products is a complex and delicate process, which mainly involves the transfer of heat energy, the evaporation of water, and the generation and collection of steam.

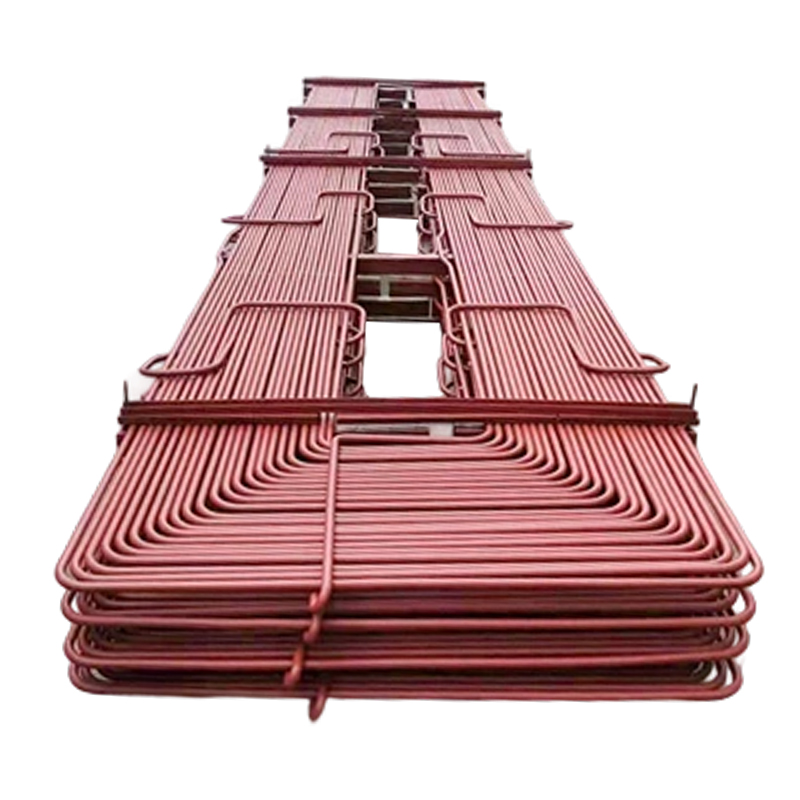

The core function of the boiler evaporator module is to use the heat energy generated by the combustion of fuel to heat water to a boiling state. Inside the boiler, fuel (such as coal, oil, natural gas, etc.) is burned and releases a large amount of heat energy. This heat energy is transferred to the water through the boiler's heating surfaces (such as the pipes and tube bundles of the evaporator). The heating surfaces are usually made of metal with good thermal conductivity to ensure efficient transfer of heat energy.

In the boiler evaporator module, water circulates through a pipe system. Usually, water enters the evaporator module from the boiler's feedwater system and then flows through pipes and tube bundles. These pipes and tube bundles are arranged inside or near the furnace to fully absorb the heat energy generated by the combustion. As the water continues to flow, its temperature gradually increases until it reaches the boiling point.

When the water temperature reaches the boiling point, the water begins to evaporate and forms steam. In the evaporator module, this evaporation process takes place inside the pipes and tube bundles. As evaporation proceeds, the water inside the pipes and tube bundles gradually turns into steam. The steam then gathers above the pipes and tube bundles to form a steam space.

The steam formed above the boiler evaporator module products is collected and transported to where it is needed through specific steam pipes. These steam pipes are usually connected to the steam outlet of the boiler to ensure that the steam can flow out of the boiler smoothly and be transported to the user end. During the steam transportation process, it may be necessary to undergo decompression, temperature adjustment and other treatments to meet the needs of different users.

In the evaporator module, the steam generated often contains a certain amount of water. In order to ensure the quality and purity of the steam, steam-water separation is usually required. The steam-water separator is an important component in the boiler evaporator module. It can separate the water from the steam and ensure that the output steam is dry. In addition, some high-end boiler evaporator modules may also be equipped with a steam purification system to further remove impurities and particles in the steam.

The thermal efficiency of the boiler evaporator module is one of the important indicators to measure its performance. In order to improve the thermal efficiency, the boiler evaporator module usually adopts a variety of energy-saving measures. For example, optimize the pipeline layout and heating surface design to reduce heat loss; use efficient insulation materials to reduce heat loss; and use advanced control systems to achieve precise control of the combustion process.

In the design and operation of boiler evaporator modules, safety and environmental protection are two crucial considerations. To ensure safety, boiler evaporator modules are usually equipped with a variety of safety protection devices, such as over-temperature protection, over-pressure protection, water level protection, etc. At the same time, in order to reduce environmental pollution, boiler evaporator modules also need to comply with relevant environmental regulations and standards, such as emission standards, energy efficiency standards, etc.

The working principle of boiler evaporator module products is a complex process involving heat energy transfer, water heating and evaporation, steam generation and collection, steam-water separation and purification, thermal efficiency and energy-saving measures, as well as safety and environmental protection considerations. Through continuous optimization of design and improvement of technology, the performance and efficiency of boiler evaporator module products have been continuously improved, providing a stable and reliable steam supply for industrial production and daily life.