How to improve the welding quality and efficiency of water wall products by using submerged arc welding automatic splicing machine?

Release Time : 2025-04-16

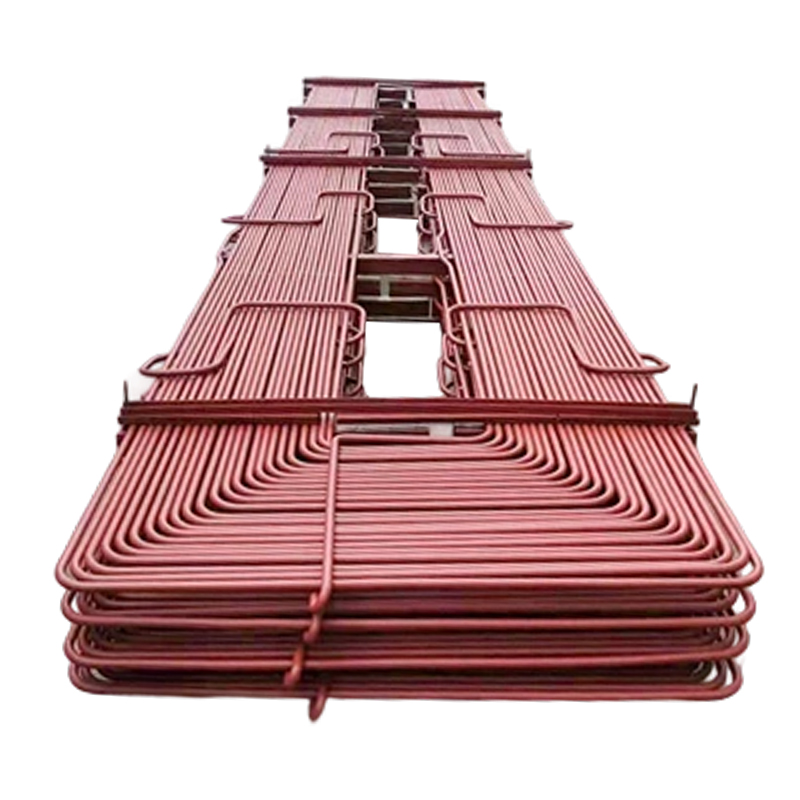

In modern industrial production, water wall is an important part of heat exchange equipment such as boilers, and its welding quality directly affects the safety and service life of the equipment. The application of submerged arc welding automatic splicing machine provides strong support for improving the welding quality and efficiency of water wall products.

First of all, the submerged arc welding automatic splicing machine improves the welding quality by precisely controlling the welding parameters. Compared with traditional manual welding, this equipment can accurately set and stably maintain key parameters such as current, voltage, and welding speed. This means that the welding conditions remain almost constant throughout the welding process, thereby ensuring the consistency of each weld. For products with extremely high requirements such as water wall, this consistency is particularly important. It not only reduces product quality problems caused by welding defects, but also greatly reduces the cost of subsequent inspection and repair.

Secondly, the improvement of automation significantly enhances welding efficiency. The submerged arc welding automatic splicing machine can operate continuously without human intervention, which greatly improves the welding output per unit time. In addition, since the equipment can handle multi-layer welding tasks at the same time, the entire welding cycle is further shortened. For water wall products produced on a large scale, this means faster market response and higher economic benefits. Moreover, the automated operation process reduces the errors and instability caused by human factors, making the product quality more reliable.

Furthermore, the submerged arc welding automatic splicing machine also has good adaptability and can be flexibly adjusted according to water walls of different specifications and shapes. Whether it is a straight pipe section or a complex elbow, a suitable welding solution can be found. This feature is due to the advanced control system and programmable logic controller (PLC), which enable the equipment to quickly adapt to different workpiece types according to the preset program. This not only broadens the application range of the equipment, but also provides technical support for customer customization needs.

In addition, the use of submerged arc welding automatic splicing machines helps to improve the working environment and protect the health of workers. Traditional manual welding processes produce a lot of smoke and spatter, which not only affects the line of sight, but also may cause harm to the welder's body. The submerged arc welding process is carried out under a layer of granular flux, which can not only effectively isolate the air and prevent metal oxidation, but also absorb most of the heat and radiation generated by welding, reducing the release of harmful substances. Therefore, after the adoption of the automatic splicing machine, the air quality in the workshop has been significantly improved, and the working comfort and safety of employees have also been improved.

Finally, it is worth mentioning that the data recording and analysis functions equipped by the submerged arc welding automatic splicing machine provide strong support for the quality management of enterprises. By real-time monitoring and recording of various parameters in each welding process, managers can view historical data at any time, analyze the welding effect, and optimize the process accordingly. For example, when it is found that the welding strength of a batch of products is lower than the standard value, the root cause of the problem can be found by tracing back the relevant data, and corrective measures can be taken in time. This data-driven quality management method helps enterprises to establish a more complete quality assurance system and continuously improve product quality.

In summary, by introducing the submerged arc welding automatic splicing machine, not only can the welding quality and efficiency of water wall products be significantly improved, but it is also conducive to creating a safer and healthier working environment and bringing long-term competitive advantages to enterprises. With the continuous advancement of technology, I believe that more innovations will be applied to this field in the future, driving the entire industry to a higher level.

First of all, the submerged arc welding automatic splicing machine improves the welding quality by precisely controlling the welding parameters. Compared with traditional manual welding, this equipment can accurately set and stably maintain key parameters such as current, voltage, and welding speed. This means that the welding conditions remain almost constant throughout the welding process, thereby ensuring the consistency of each weld. For products with extremely high requirements such as water wall, this consistency is particularly important. It not only reduces product quality problems caused by welding defects, but also greatly reduces the cost of subsequent inspection and repair.

Secondly, the improvement of automation significantly enhances welding efficiency. The submerged arc welding automatic splicing machine can operate continuously without human intervention, which greatly improves the welding output per unit time. In addition, since the equipment can handle multi-layer welding tasks at the same time, the entire welding cycle is further shortened. For water wall products produced on a large scale, this means faster market response and higher economic benefits. Moreover, the automated operation process reduces the errors and instability caused by human factors, making the product quality more reliable.

Furthermore, the submerged arc welding automatic splicing machine also has good adaptability and can be flexibly adjusted according to water walls of different specifications and shapes. Whether it is a straight pipe section or a complex elbow, a suitable welding solution can be found. This feature is due to the advanced control system and programmable logic controller (PLC), which enable the equipment to quickly adapt to different workpiece types according to the preset program. This not only broadens the application range of the equipment, but also provides technical support for customer customization needs.

In addition, the use of submerged arc welding automatic splicing machines helps to improve the working environment and protect the health of workers. Traditional manual welding processes produce a lot of smoke and spatter, which not only affects the line of sight, but also may cause harm to the welder's body. The submerged arc welding process is carried out under a layer of granular flux, which can not only effectively isolate the air and prevent metal oxidation, but also absorb most of the heat and radiation generated by welding, reducing the release of harmful substances. Therefore, after the adoption of the automatic splicing machine, the air quality in the workshop has been significantly improved, and the working comfort and safety of employees have also been improved.

Finally, it is worth mentioning that the data recording and analysis functions equipped by the submerged arc welding automatic splicing machine provide strong support for the quality management of enterprises. By real-time monitoring and recording of various parameters in each welding process, managers can view historical data at any time, analyze the welding effect, and optimize the process accordingly. For example, when it is found that the welding strength of a batch of products is lower than the standard value, the root cause of the problem can be found by tracing back the relevant data, and corrective measures can be taken in time. This data-driven quality management method helps enterprises to establish a more complete quality assurance system and continuously improve product quality.

In summary, by introducing the submerged arc welding automatic splicing machine, not only can the welding quality and efficiency of water wall products be significantly improved, but it is also conducive to creating a safer and healthier working environment and bringing long-term competitive advantages to enterprises. With the continuous advancement of technology, I believe that more innovations will be applied to this field in the future, driving the entire industry to a higher level.